Unearth the Power of Peat

Clean water matters. That’s why we transform natural reed-sedge peat into engineered granular products that use sorption to remove metals such as lead, cadmium, copper, zinc and nickel during the water remediation process. It’s time to take charge of your water. It’s time to unearth the power of peat.

Because of the geochemical environment of peat deposits, reed-sedge peat tends to reject innocuous metals such as calcium and magnesium while attracting and bonding with more toxic metals such as lead and cadmium. That means that more of your investment goes into solving the problem, instead of paying for treatment that you don’t need. Are you ready to harness the power of APTsorb® and APTIVATOR™ to meet your water treatment goals?

Our partner, Headwater Technologies, is the exclusive distributor of our granular peat media products. Headwater Technologies is a team of water treatment professionals committed to providing the most effective solution for each situation.

Explore Peat ProductsModern lifestyles require a lot of water. The average American uses 80-100 gallons of water each day and many industries use hundreds of thousands of gallons each day to manufacture the products and materials we rely on. Water is simply too precious to treat as disposable. When heavy metals and particulates are a concern, use robust, economical peat-based water remediation products from APT. APTsorb® and APTIVATOR™ are designed to remediate contamination and prepare water for reuse or release.

Robust Response

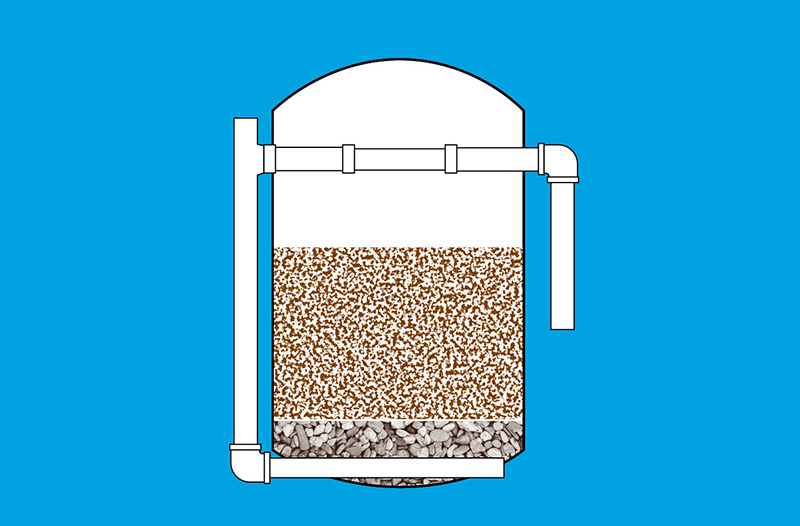

APTsorb and APTIVATOR can be deployed in challenging conditions that may be problematic for other resins. It tackles difficult suspended solids without fouling the media surface or compromising its sorption capacity. Add APT water remediation products to the front end of a water treatment train to protect valuable, high-end resins and treatments from solids. The media can be backwashed in pressure vessels to remove particulates and extend treatment life.

Economical solution

APT’s water remediation products are low-cost, low-input answers to complex water treatment problems. The robust nature of the media translate into less infrastructure and labor costs. Talk to our experts about how to design an effective and efficient treatment system that takes advantage of the unique characteristics of APTsorb or APTIVATOR while meeting your compliance goals.

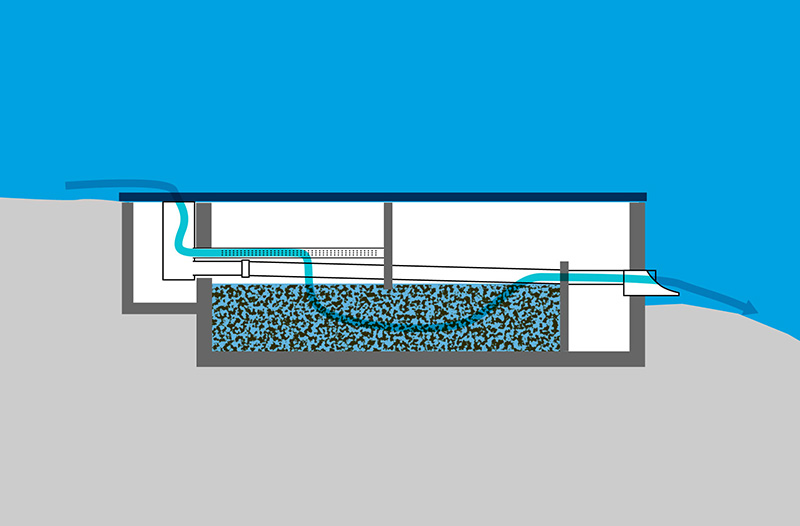

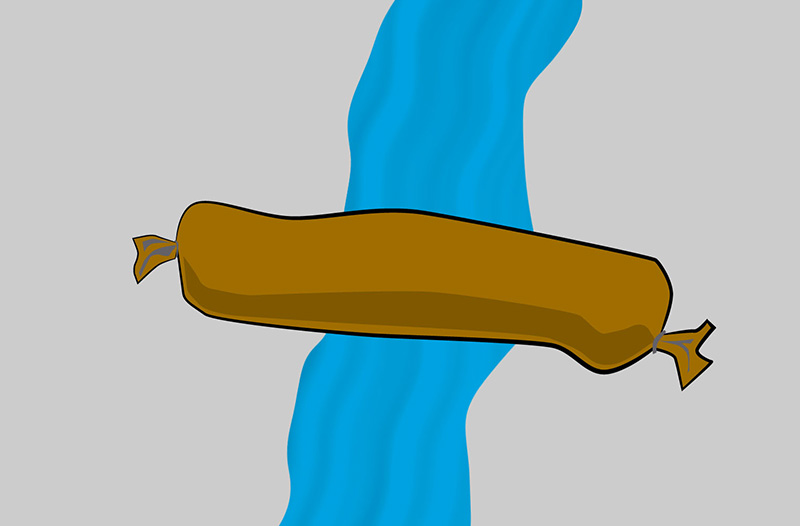

APTsorb® and APTIVATOR™ can be used in almost any structure, tank, vault, boom sock or in-ground cell as long as the flow rate can be controlled and good media/water contact can be made. They are cost-effective for most applications and can be used in a treatment train to polish water prior to discharge or to remove selected ions within the treatment system.

There are a few things to keep in mind when considering a retrofit to APTsorb or APTIVATOR.

- APTsorb and APTIVATOR are organic sorption products, so they require a certain amount of contact time. More specifically, the performance of the media is sensitive to the velocity of the water. If the water is flowing too quickly, the peat surface does not have time to form bonds with the metal ions as they travel past. Recommended velocities are dependent on the type of metal, concentration levels and background chemistry, but a general rule of thumb is to keep the velocity less than 33 ft/hr (10 m/hr). Contact us for help to design a system with optimal flow rates.

- In most cases, it is preferable to keep the ratio of bed height to bed diameter less than one. A shorter, squatter contactor is preferred over a taller, thinner vessel. Given the recommended velocities above, this configuration allows for a favorable volume of water to be treated while maintaining the residence time.

- A lead/lag system will extend the life of APTsorb and APTIVATOR, as well as allow for some shortcomings in system design. The many mechanisms at work in the natural peat have different coefficients of performance, which means that the peat surface responds robustly to different system parameters. A lead/lag system can utilize more of the different loading mechanisms than a single-pass treatment system.

- In addition to its sorptive capacity, APTsorb will act as a physical filtration media. The angular, polar surfaces of the media are very effective at sequestering solids within the bed. The efficacy of APTsorb depends on the characteristics of the solids, but removals exceeding conventional sand filters are possible.

- If suspended solids are a concern, a vessel that allows for backwashing will extend the life of the APTsorb media. Backwashing rates can vary depending on the nature of the solids, but 10-15 gpm/ft2 is sufficient to lift the APTsorb bed in most cases.

- Regeneration of APTsorb and APTIVATOR is not recommended. The peat surface forms very stable double bonds with metal ions, and regeneration is usually incomplete and unwieldy. Once the media is exhausted, disposal is recommended.

- Disposal of spent APTsorb and APTIVATOR is dependent on local regulations and how the media was loaded. We recommend performing a TCLP test (EPA 1311) or total constituent analysis on the media. For most metals, with the exception of lead, under normal loading conditions, we anticipate that the media will pass the TCLP.

Contact us for more information about how to retrofit or design a system for APTsorb or APTIVATOR treatment.

Prior to deploying our peat-based water remediation products in new applications, a treatability test can offer some assurance that you’ve selected the right solution. We often provide complimentary treatability testing in our research and development lab. Our tests assess the effectiveness of our media against your specific water. Please contact us to talk about treatability testing, and expect to provide some preliminary information such as the following:

- What type of water are you treating (stormwater, mine dewatering discharge, truck wash water, etc.)?

- What are the metals of concern?

- What are the concentrations of the metals of concern?

- What is the effluent target concentration?

- What volumes need to be treated?

- What flow rates need to be treated?

- What other background metals are present? (If you have any characterizations, monitoring reports, etc. that would be helpful.)

- How is the water currently being treated?

- What other treatment systems have been tried?

- What are the site limitations (small footprint, airborne contaminants, etc.)?

Contact us for more information about how to retrofit or design a system for APTsorb and APTIVATOR treatment.

Peat as a Sorption Media

Reed-sedge peat is a complex material consisting mostly of lignin, hemicellulose, cellulose and humic substances. These constituents bear functional groups such as carboxylic acids and hydroxides that are primed and ready for chemical bonding. Further, it’s the negative charge of these functional groups that make peat a star performer against toxins with a positive charge, including the cationic form of many heavy metals.

With such an extensive list of functional groups, it’s little wonder that the mechanisms of sorption for APTsorb®, APTIVATOR™ and natural peat remain under debate. The current literature surrounding peat typically describes five primary mechanisms of sorption.

Although definitive answers are elusive, the primary mechanisms of sorption in APTsorb and APTIVATOR appear to be complexation, chemisorption and ion-exchange.

The APT Advantage

Natural peat has too many short-comings to be used as-is. Raw peat does not have favorable hydraulic characteristics because water simply doesn’t want to flow through it. As a result, when raw peat is used as a water remediation media, large amounts of sand or other coarse material must be added to maintain hydraulic conductivity in the bed. Also, raw peat is dusty and difficult to wet, and its low density makes shipping a challenge.

APT’s water remediation products harness the attractive qualities of peat while overcoming the shortfalls. APTsorb is a hardened granular media with a hydraulic conductivity of about 1 cm/sec. It is a robust media that can contend with variations in influent water. APTIVATOR is a spherical media that can be produced in a variety of sizes depending on system design and permeability parameters. Both APTsorb and APTIVATOR work without extra sand, so 100 percent of the treatment bed is dedicated to metals sequestration.

APTsorb/APTIVATOR: Under the Surface

APTIVATOR Product Data Sheet

APTsorb Product Data Sheet

APTsorb/APTIVATOR Safety Data Sheet