When Healthy Crops Matter

Healthy crop growth starts below the ground. It’s no secret that historical agricultural processes relied heavily on chemical treatments. Today, both producers and consumers understand there are natural and more sustainable ways to feed our growing population. It all starts with taking care of the soil, because what happens below the ground is just as important, if not more, than what grows above it. Reed-sedge peat has been used as a natural microbial carrier for centuries. BioAPT builds on that historical use by transforming raw, unprocessed peat into a consistent granular media that meets strict quality control standards for pH, moisture content and particle size. BioAPT is available in both granular (0.3 mm to 2 mm) and powdered (minus 150 µm) forms. Throughout North America, BioAPT is the granular peat-based Rhizobia carrier of choice and is used to inoculate millions of acres of food crops each year. Quality. Consistency. Innovation. Our advanced production process and strict quality control parameters result in a consistent, quality product season after season, year after year. What makes us different?

- We have exclusive access to a high-quality peat source in central Minnesota. Because APT manages the harvest permit, our BioAPT products are manufactured from the same peat source every year.

- Our state-of-the-art production processes make it possible for us to produce a large volume of media within extremely tight parameters.

- We embrace a strict quality control protocol to identify media that is out of specification and remove it from the production process.

Questions about how to use BioAPT? Contact our in-house experts.

Peat and agriculture have gone hand-in-hand for hundreds of years. APT has built upon that natural synergy — and then surpassed the historical use of peat — by investing in innovative processes to meet the challenges of today’s complex agriculture markets. APT’s microbial carriers are the backbone of PGPM formulations that are used throughout the western hemisphere. In addition, our on-going research and development into other carrier applications is resulting in granular micronutrient products that fight soil deficiencies, microbial carriers manufactured from alternative raw materials, and products that play a role in the move toward precision agriculture. With other innovative technologies, BioAPT is helping to feed the world.

Historically Superior

Peat has been used as a microbial carrier for over a hundred years. BioAPT can be supplied as a powder or as a granule, offering multiple solutions for differing farming practices.

Consistently engineered BioAPT is chemically and physically uniform because the raw peat material is harvested from a single, relatively homogenous peat deposit. The natural acidity of the parent peat material is buffered through the addition calcium carbonate.

OMRI Listed

APT makes granular and powdered BioAPT in organic forms. Our BioAPT Org products are listed by the Organic Materials Review Institute. We are happy to work with your organic certifier to make sure your end product meets the standards for organic listing.

Scientifically Sound

BioAPT is adaptable to many different microorganisms and is suitable for plant growth promoting rhizobacteria (PGPR) and other plant growth promoting microorganisms (PGPM). Porous and hydrophilic properties capture added nutrients for microbial survival and growth.

Environmentally Friendly

Peat is a natural product composed of partially decomposed plant matter. Raw peat is a valuable soil amendment that increases organic content of soils and improves water holding capacity.

Responsibly Produced

American Peat Technology has been producing a superior carrier media since 2003. We retain total control over the entire BioAPT production process and have passed manufacturing efficiencies on to our customers, resulting in a fair and consistent pricing structure and steady company growth.

Safely Deployed

Our production process uses heat sufficient to render the media nearly sterile when shipped. BioAPT is non-toxic, safe for workers and shipped in easy-to-manage, easy-to-store super sacks. Prior to inoculation, BioAPT can be stored for years without a loss of effectiveness.

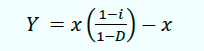

Depending on the moisture level required for different formulations, BioAPT’s moisture content may need to be adjusted to achieve final targets. The rewetting process can be conducted quickly and efficiently onsite. Use the equation below to calculate the amount of liquid to add in order to reach the targeted moisture level.

How to Adjust BioAPT Moisture Content

1. Determine the moisture content of a well-mixed sample of dry media.

2. Use the following formula to determine how much water to add to reach a target moisture:

where: Y = mass of water needed (gms or lbs)

x = mass of sample (gms or lbs)

i = initial moisture content, expressed as decimal

D = target moisture content, expressed as decimal

3. Add calculated water needed (Y).

4. Mix well. Let stand for 15 minutes. The sample should be free-flowing and not sticky.

Questions about how to use BioAPT? Contact our in-house experts.